The industrial sector accounts for over half the total electricity

consumption, of which 60 to 70% is utilized by electric motors.

This indicates that electric motors consume more energy than

any other application.

A typical electric motor's average lifespan ranges anywhere

between 15 to 20 years depending on the quality of raw material

and manufacturing process. The operational cost of a motor is

around 95% of the total life cycle cost. With a steadily increasing

installed base of electric motors, our nation has a tremendous

opportunity to save energy.

The purpose of energy efficiency labeling is to overcome the lack

of awareness and also help end-users in selecting from a range of

energy-efficient products. While the developed world has kept

pace with energy efficiency measures, the developing countries

have been slower in implementing them for electric motors.

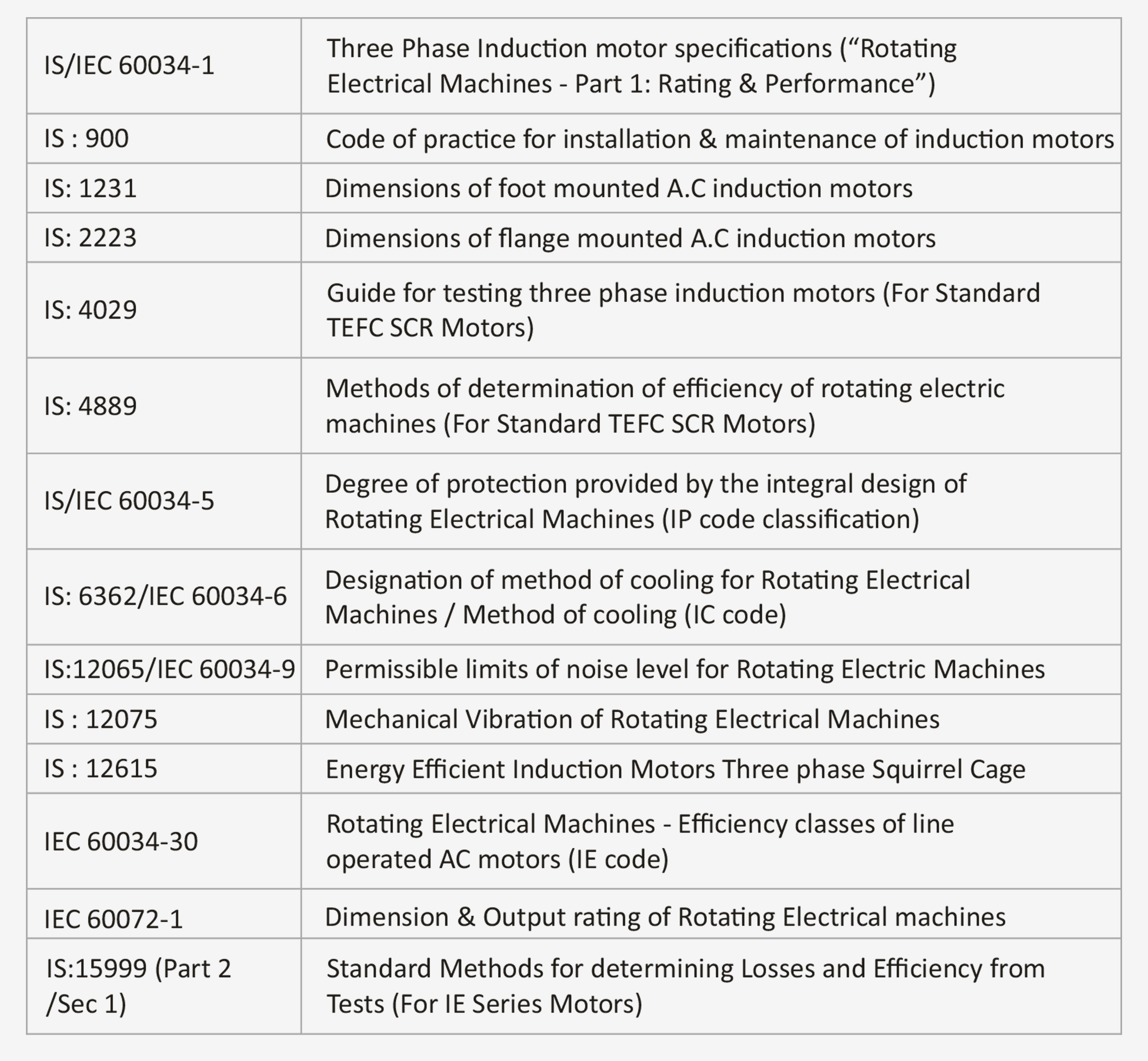

Reference Standards

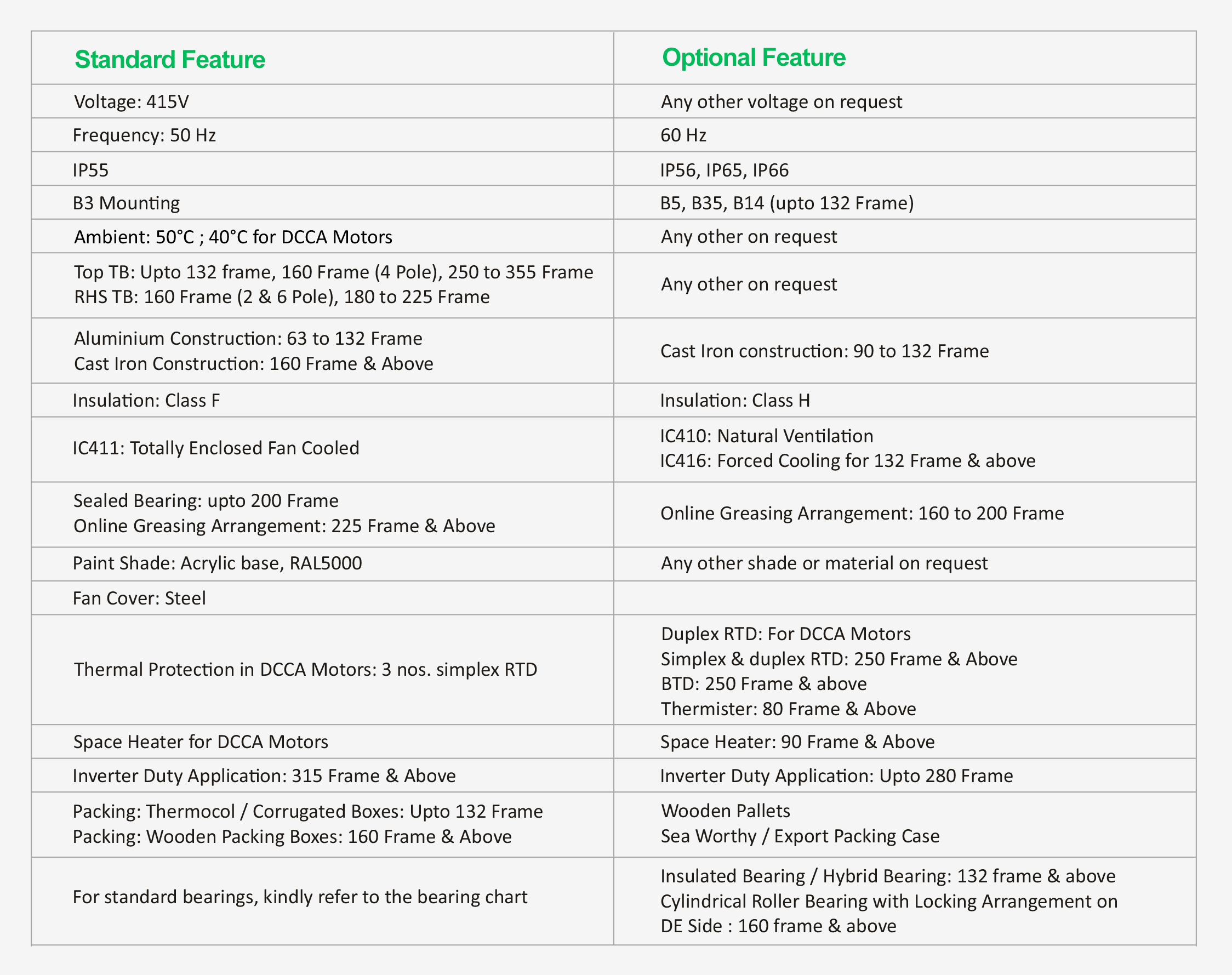

General Technical Specifications

Range

- Series: 3 Phase Squirrel Cage Induction, Safe Area Motors.

- kW Rating: 0.37 to 355

- Frame: 71 to 355

- Polarity: 2, 4, 6

Our Other Optional Features:

- Higher polarity

- Motors suitable for inverter duty application for all voltages

- Motors suitable for S2 to S9 duty operation

- VPI upto 280 frame

- Non standard shaft material, diameter & extension

- Front bearing locking arrangement

- SS Hardware, Canopy, non standard paint & paint shade, cable gland

- Provision for hollow shaft encoder mounting

- High temperature grease

- Reduced & Special grades of vibration as per IS 12075 can be provided on request.

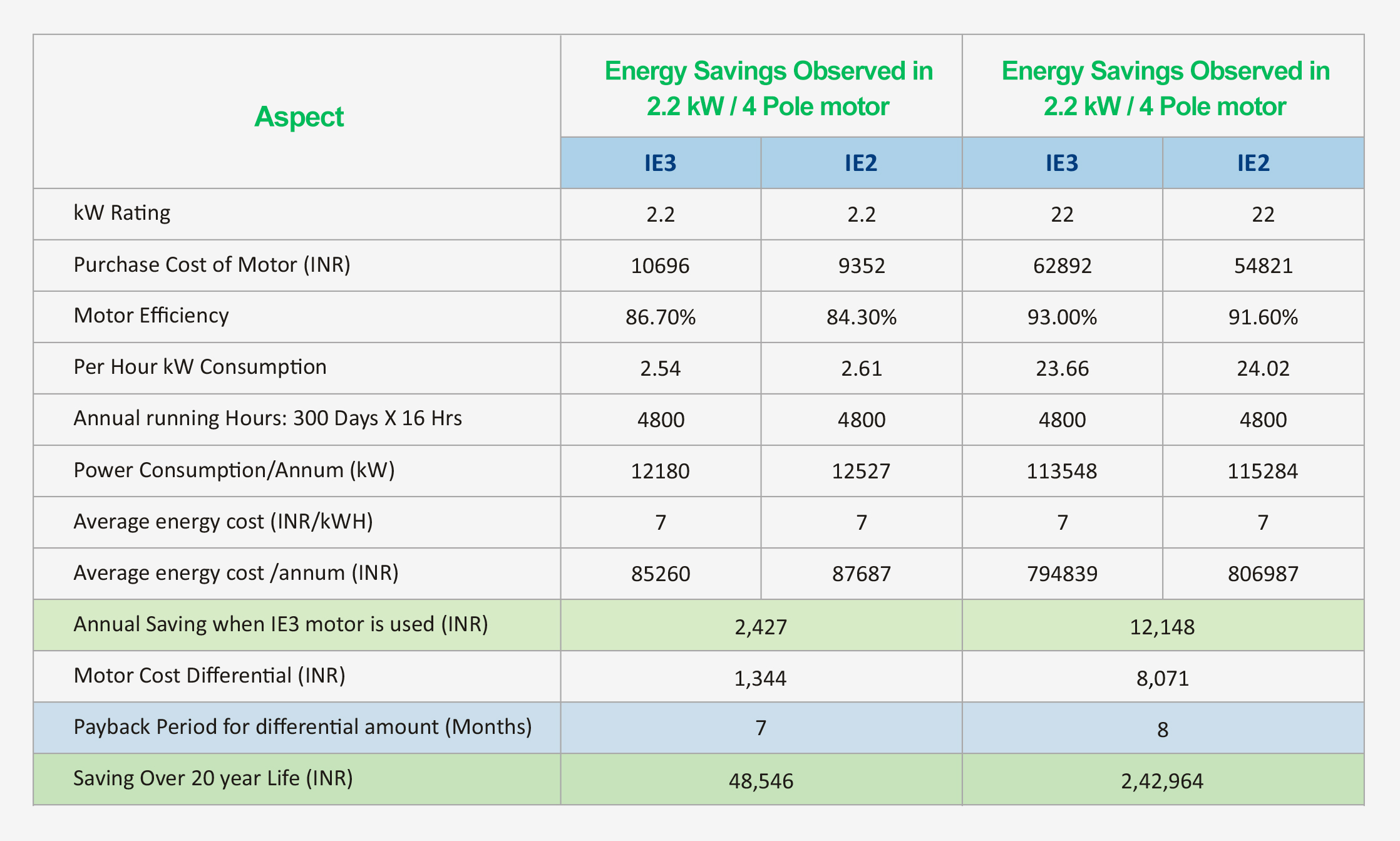

Why going for High Efficiency